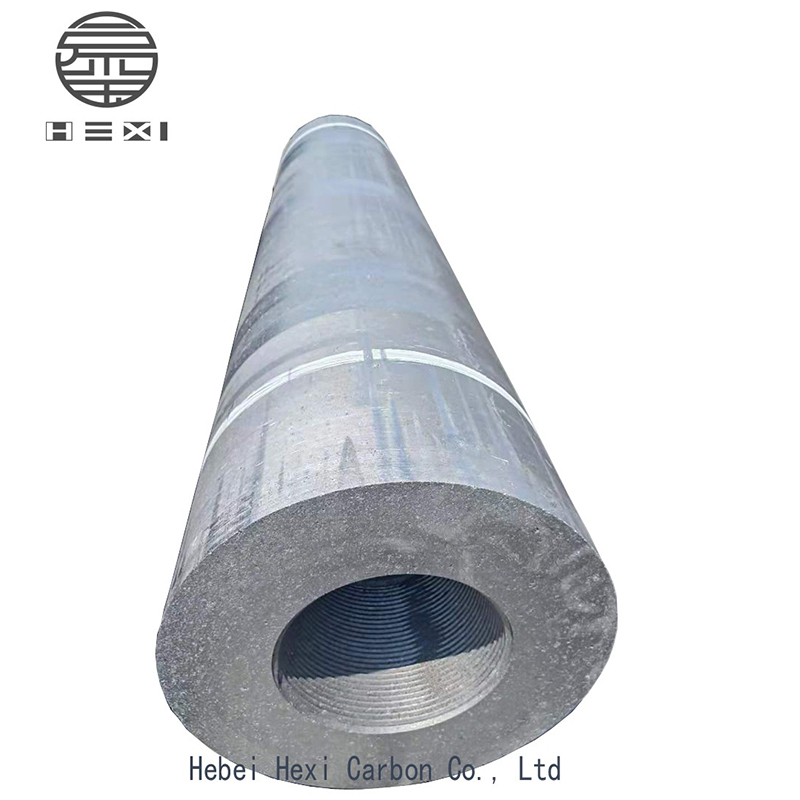

450mm yakakwirira simba graphite electrod

HP graphite electrode inonyanya kugadzirwa nepetroleum coke uye tsono coke, Inokwanisa kutakura density iripo 18-25A/cm2. Yakagadzirirwa yakakwirira simba remagetsi arc furnace simbi-kugadzira.

| Kuenzanisa Unyanzvi Kutsanangurwa kweHPGraphite Electrode18″ | ||

| Electrode | ||

| Item | Unit | Supplier Spec |

| Typical Characteristics of Pole | ||

| Nominal Diameter | mm | 450 |

| Max Diameter | mm | 460 |

| Min Diameter | mm | 454 |

| Nominal Length | mm | 1800-2400 |

| Max Length | mm | 1900-2500 |

| Min Length | mm | 1700-2300 |

| Bulk Density | g/cm3 | 1.68-1.73 |

| mhiri simba | MPa | ≥11.0 |

| Young' Modulus | GPa | ≤12.0 |

| Chaiyo Resistance | µΩm | 5.2-6.5 |

| Maximum current density | KA/cm2 | 15-24 |

| Ikozvino Kutakura Kugona | A | 25000-40000 |

| (CTE) | 10-6 ℃ | ≤2.0 |

| ash content | % | ≤0.2 |

| Mamiriro Akajairika eNipple (4TPI/3TPI) | ||

| Bulk Density | g/cm3 | 1.78-1.83 |

| mhiri simba | MPa | ≥22.0 |

| Young' Modulus | GPa | ≤15.0 |

| Chaiyo Resistance | µΩm | 3.5-4.5 |

| (CTE) | 10-6 ℃ | ≤1.8 |

| ash content | % | ≤0.2 |

Nzira yekudzikisa kushandiswa kwe electrode

Mumakore achangopfuura, nekusimudzira kwakasimba kweChina yemagetsi muchoto simbi indasitiri, pamwe nezvinodiwa zvekuchengetedza simba uye kuderedzwa kwekushandisa nyanzvi nyanzvi uye nyanzvi kumba nekune dzimwe nyika vanopedzisa dzimwe nzira dzinoshanda sezvizvi:

1.Anti-oxidation mechanism yemvura spray graphite electrode

Kuburikidza neongororo yekuedza, kupfapfaidza anti-oxidation mhinduro pamusoro pemaelectrodes kwakaratidza zvirinani pakumira kubva kudivi oxidation yegraphite electrode, uye iyo anti-oxidation simba inowedzerwa ne6-7 nguva. Mushure mekushandisa nzira iyi, kushandiswa kwe electrode kwadzikira kusvika 1.9-2.2kg kunyungudutsa toni yesimbi.

2.Hollow electrode

Mumakore achangopfuura, Western Europe neSweden dzakatanga kushandisa maelectrode asina mhango mukugadzira mavhiri echicherwa cheferroalloy. Hollow maelectrodes, silinda chimiro, anowanzo asina chinhu mukati akavharwa neinert gasi. Nekuda kwehukomba, mamiriro ekubikira anovandudzwa uye anoita kuti simba re electrode riwedzere. Kazhinji, inogona kuchengetedza maelectrodes ne30% -40%, kusvika pa50% zvakanyanya.

3.DC arc furnace

DC yemagetsi arc furnace imhando nyowani yekunyungudutsa yemagetsi arc furnace ichangobva kugadzirwa munyika mumakore achangopfuura. Kubva kune yakadhindwa data kunze kwenyika, DC arc furnace ndiyo imwe yeanonyanya kushanda matekiniki ekuderedza kushandiswa kwemagetsi. Kazhinji, kushandiswa kwe electrode kunogona kuderedzwa neanenge 40% kusvika 60%. Sekureva kwemishumo, iyo graphite electrode kushandiswa kwehombe-yepamusoro-yepamusoro-yepamusoro simba remagetsi vira remagetsi yakaderedzwa kusvika 1.6kg/t.

4.Electrode surface coating teknolojia

Electrode coating tekinoroji iri nyore uye inoshanda tekinoroji yekudzikisa kushandiswa kwemagetsi, kazhinji inogona kuderedza kushandiswa kwemagetsi ne20%. Inowanzoshandiswa electrode coating zvinhu aruminiyamu uye zvakasiyana-siyana zvedomi zvinhu, ane yakasimba oxidation kuramba patembiricha yepamusoro uye anogona zvinobudirira kuderedza oxidation kushandiswa kweelectrode divi pamusoro. Nzira yekuputira electrode inonyanya kupfapfaidza nekukuya, uye maitiro ayo ari nyore uye ari nyore kushandisa. Ndiyo nzira inonyanya kushandiswa yekudzivirira electrode.

5.Impregnated electrode

Dip electrode mumushonga wemakemikari kuti ukonzere kusangana kwemakemikari pakati penzvimbo ye electrode uye maajenti kuti avandudze kuramba kwe electrode kune yakanyanya-tembiricha oxidation. Mhando yemagetsi emhando iyi inogona kuderedza kushandiswa kwemagetsi nechikamu che10% kusvika 15%.